The physics department at UBC has a student machine shop, which is accessible to students. They require a training course to gain access to this facility, to ensure proper and safe use of the machinery. Given my experience with hands on fabrication from working with NorthForge over the summer, I decided taking this course would be a great opportunity to get additional hands-on experience with engineering skills.

The course covered how to use lathes and mills, both manually controlled. It was both exciting and terrifying using these devices. The amount of precision required to create a part, particularly when a single misplaced cut could ruin five hours worth of work, was terrifying. It really stressed a “measure twice, cut once, and then measure again to make sure you made the cut correctly”. Additionally, I learned the importance of properly dimensioning a part, and how tolerances impacted how difficult a component was to make.

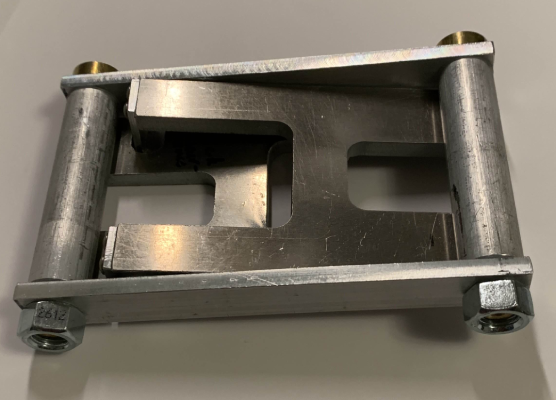

The course taught these skills through the creation of a phone stand. A waterjet cutter was used to cut out the blanks for the base and mount, and arms, and then dimensions and features were applied using the mill. Brass screws were made on the lathe, as well as aluminum mounts.

The most thrilling parts to make were the small feet upon which the phone rests. These parts are only eighty thousandths of an inch thick. Maneuvering the mill head spinning at hundreds of RPMs mere thousandths of an inch above the vice, using an old analog readout to measure position, was probably the scariest thing I had to do last year.

Ultimately, I’m happy with how my project turned out. I spent about fourty hours in the machine shop, twenty of which were direct instruction, and twenty of which were independant work under instructor supervision